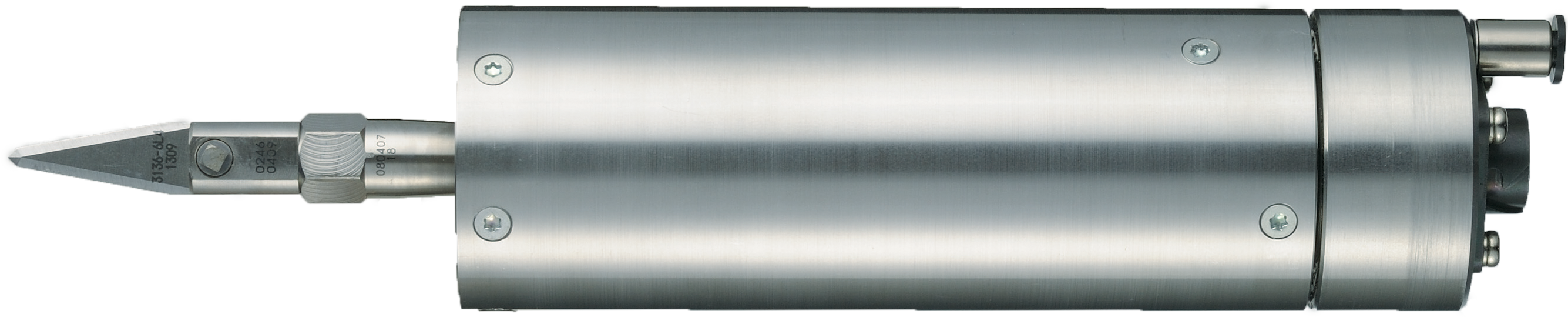

SF-8500RR | SH-3510

Transducer : SF-8500RR

This is a large amplitude type where the blade vibration amplitude is made larger than conventional models. With a 42 mm diameter cylindrical shape, the model is easy to be mounted on automated machinery, industrial robots and plotters. It is best suited for cutting and punching processing of 3D parts by mounting on industrial robots, in addition to processing of sheets and punching.

SH-3510 specification click here

Specifications:SF-8500RR

| Frequency | 22kHz |

|---|---|

| Cord length | Up to 10 m |

| Housing material | SUS303 |

| Weight | 650g |

| Blade thickness | The thickness depends on the specifications of holder (0.4 to 1.0 mm) |

Applicable Materials

|

|

plate, sheet, film, and laminated material |

|---|---|

|

|

carbon fibers(CFRP) |

|

|

polyethylene fiber,molded articles containing carbon or glass fibers (GFRP) |

|

|

vulcanized latex, non-vulcanized latex, sheeting material, and tube |

Click here to download the dimensions and catalogs

Click here to apply for a test cut and Inquiries

Apply for test cut by fax

Apply for a test cutting by phone

Period of acceptance weekdays from 9:00 a.m. to 5:00 p.m.(Japan time)

Oscillator:SH-3510

Upgraded: Connection with PLC is now available

Factory improvement through DX/loT requires connection with various controllers and connection with PLC is now available besides the conventional relay control by ON/OFF switching. Standard installation of analog signal output for the load/amplitude and additional digital signals for each oscillation frequency/error type allow outputting more detailed data now.

Specifications:SH-3510

| Frequency adjustment | Automatic tracking type | |

|---|---|---|

| Maximum output | 500W | |

| Output adjustment | Step-less continuously variable type | |

| Power requirement | Single phase 200 VAC, 50/60 Hz |

|

| Power consumption | 1000VA | |

| Outer dimension (mm) | 300W × 400D × 200H | |

| Weight | 11kg | |

| Function | Detection of error cause | |

| External device connection function | Input | Oscillator ON/OFF, Amplitude adjustment. Error recovery |

| Output |

DC analog output. Frequency pulse output. Load threshold warning, Power supply status monitor,Error detection |

|

Transducer combined with SH-3510

- Machine / robot-mounted type

- Manual-type hand piece

| Combination transducers | Frequency | Applicable materials | ||

|---|---|---|---|---|

|

HP-8701-C3 | 24kHz |     |

|

|

HP-2000 | 20kHz |    |

|

|

SF-3110 | 20-22kHz |    |

|

|

SF-8500RR | 22kHz |     |

|