COLUMN

Ultrasonic Cutter / Polisher columns

Ultrasonic Cutter Principle

Ultrasonic equipment

Ultrasonic machines include ultrasonic processing machine, ultrasonic welding machine, ultrasonic cleaner machine, ultrasonic dispersion machine, ultrasonic measuring instruments, ultrasonic levitation, etc. and we specialize in ultrasonic processing machine. We deal with ultrasonic cutters that can cut materials with less resistance or ultrasonic polisher that can polish metal such as molds with high efficiency by making use of ultrasonic wave to transmit oscillation to tools.

What is the cutting done by the ultrasonic cutter?

Ultrasonic cutter vibrates its blade 20,000 - 40,000 times per second (20 - 40 kHz). Because of this movement, the ultrasonic cutter can easily cut resin, rubber, nonwoven fabric and composite materials. Besides being excellent in maintainability, our products are environment-friendly as they do not substantially discharge any crumbs, waste water, noise, or smoke.

How does ultrasonic cutter work?

Each object has its special frequency, by which the object is stable and easy to oscillate. By adding an external force that corresponds to that special frequency, a small force can obtain a large oscillation. This phenomenon is called resonance. The cutting edge is oscillated greatly with the use of resonance.

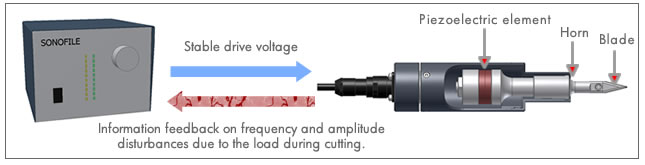

The ultrasonic cutter is composed of a "transducer" that generates oscillation and an "oscillator" that drives the transducer. Piezoelectric elements are incorporated in the transducer, and by applying an AC voltage aligned with the characteristic frequency of transducer from the oscillator to the piezoelectric element, the entire vibrator including the cutter blade is resonated. Transducer comes with feedback-control system which transmits information of frequency or amplitude deviation to oscillator caused by cutting load. The feedback-control system can keep resonance state and amplitude of blade stable and it enable the cutters always to cut materials sharply and cleanly.

Watch sample cut video of

ultrasonic cutter

Request a free test cut

Please send your sample. After the test cut is completed, you will receive a video and data taken during the cutting process along with the sample cuts.